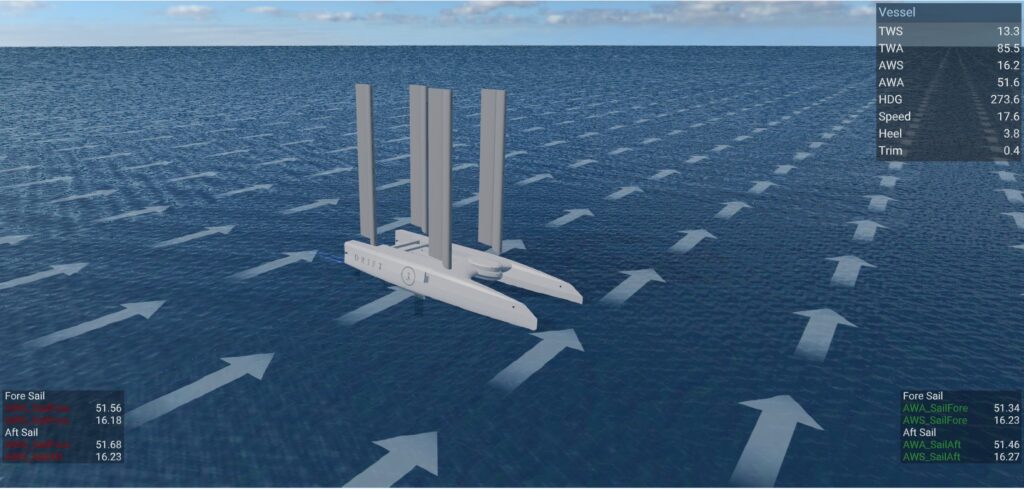

Gomboc Designer is now being used to model the ships’ performance holistically . With support from Cape Horn Engineering, high-fidelity computational fluid dynamics (CFD) are used to model the real-world performance of the sails, hulls, turbines and appendages. From here, the engineers at DRIFT create surrogate models to integrate the CFD data seamlessly into the ship model, turning modular insight into a comprehensive view of vessel performance and power generation. For each design configuration, DRIFT generates hundreds of performance points, consisting of tens of thousands of parameters, to understand the vessel’s performance in all conditions. This performance data is then fed into DRIFT’s proprietary ‘GOLDILOCKS’ routing software to optimise the vessel’s energy generating routes over hundreds of virtual years and millions of virtual nautical miles. This precise and intricate optimisation process is allowing DRIFT to design their vessel to ‘go greener’, delivering more energy, more of the time.